CNC Solutions UK

CNC Training & Support Services

+44(0) 7977 290044 | sales@cnc-solutions-uk.co.uk

CNC Solutions UK

CNC Training & Support Services

+44(0) 7977 290044 | sales@cnc-solutions-uk.co.uk

We deliver CNC Training from beginners to advanced on a wide range of machine tools including Fanuc Heidenhain, Siemens, Haas and many more on most well known machine tools. we can offer onsite visit and courses at our facility - Please contact for more info.

We offer project work in either new product introduction from design to manufacture. Best practice and cycle time reduction.

Improve your productivity with our experienced team of engineers.

We are UK distributors of Cimco dnc and programming editing software. Transfer programs to and from your machine tools effortlessly and archive them in allocated folders,

Please contact for more info

Siemens and Heidenhain controls conversational programming courses delivered from operating , programming and using advanced features for both Milling and Turning.

Best practice training can be added to cover tooling, setup and methods, a key to getting the most out of your CNC Machine.

We offer courses on older or less common controls , Fagor or Boss for example. Tailor this with best practice training can be added to cover tooling, setup and methods, a key to getting the most out of your CNC Machine.

Multi-Axis cnc machines look complex but with the right methodical training we can bring you up to speed with modern machinery, live tooling, sub-spindle, multi turrets and twin spindle with Y axis the sky is the limit , combine this with best practice training can be added to cover tooling, setup and methods, a key to getting the most out of your CNC Machine.

CNC Solutions offers training courses that cover all aspects of the machine lifecycle, from maintenance to operator and programmer training if you’re looking to secure a career in engineering with CNC machine tools.

We run a comprehensive range of CNC turning and milling (including 5-axis, mill-turn and multi-tasking turning centre) training courses for all abilities (beginner through to advanced, and operator through to programmer), and for all main CNC control systems (Fanuc, Siemens, Heidenhain) as well as a number of specialist courses – Manual Guide, FeatureCam, etc.

Siemens CNC Operator course content.

A. basic introduction to the relevant machine tool (i.e. machining centre or lathe);

B. An explanation of machine tool and machining terminologies and principles;

C. An introduction to the specific CNC control and its functions;

D. An understanding of offsets (i.e. workpiece and tool length etc.) including how to set and adjust parameters;

E. Health and Safety compliance and best practice.

Standard Siemens Shopturn Programming content.

Using the Siemens’ ShopTurn function helps fast and efficient programming. The course consists of step-by-step instructions beginning with basic principles and gradually increasing in complexity. Specific descriptions and programming examples will also be covered in the course.

By the end of the course, you should be able to program components to a reasonable standard, thus achieving the full potential of your CNC turning centres.

Applicants should have a basic knowledge of Engineering and an understanding of component drawings would be advisable.

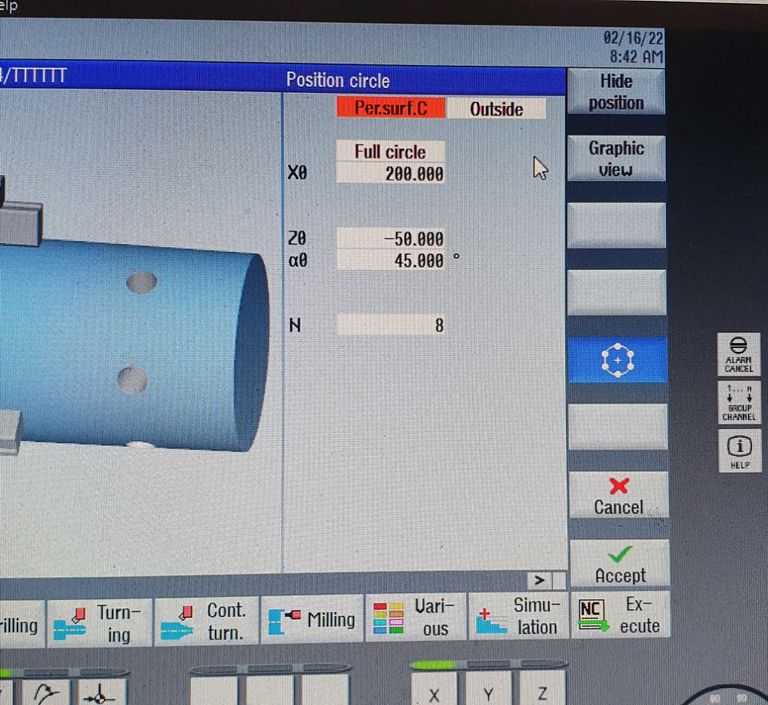

Specific course content includes: Introduction and General Layout of Machine Operator, Keyboard and Soft-key Explanation Axes Configuration X, Z, C and Y if required Modes e.g. T, S, M and MDA and Program Manager Tool List Creation and Editing and Work Offset Menus Create Shop Turn Program with Program Header Planning the Machining Process and Structure Contour Turning and Utilising Shop Turn to include Turning, Facing and Boring Cycles Hole Machining with Drilling, Tapping Cycles etc. Simulating and Troubleshooting Programs Grooving, Part Off, Threading Cycles Drilling, Tapping and Thread Milling Cycles Using C or Y Axis Pocket, Spigot and Engraving Milling Cycles Using C or Y Axis Set Marks, Repeats in Sub Routines Transformations Offset, Rotation Mirroring etc. Explanation of Counter Spindle and Transfers if required Description of M codes relative to type of Machine Examples Utilising the Above USB communication to machine

Advanced Siemens Shopturn Programming content.

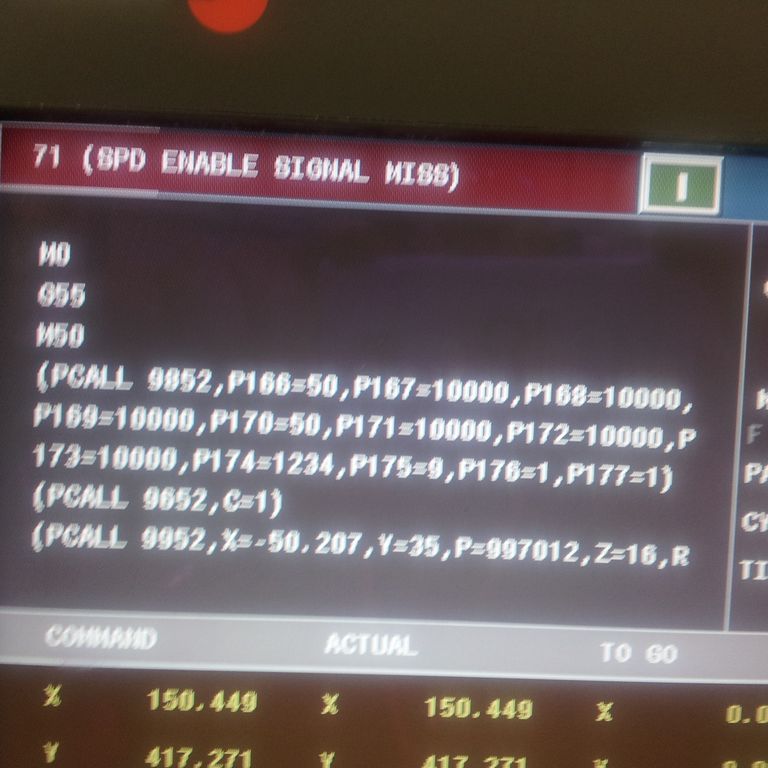

Using the Siemens’ ShopTurn function, along with ISO codes and Parametric functions, helps fast and efficient programming. The course consists of step-by-step instructions beginning with basic principles and gradually increasing in complexity. Specific descriptions and programming examples will also be covered in the course as well as showing both turrets working simultaneously. Subjects covered in the course include:

Milling and drilling on angles

Working both sides

Balanced machining times

By the end of the course, you should be able to program components to a reasonable standard, thus achieving the full potential of your CNC Twin Spindle and Twin Turret turning centres.

Applicants should have a basic knowledge of Engineering and an understanding of component drawings would be advisable.

Specific course content includes:

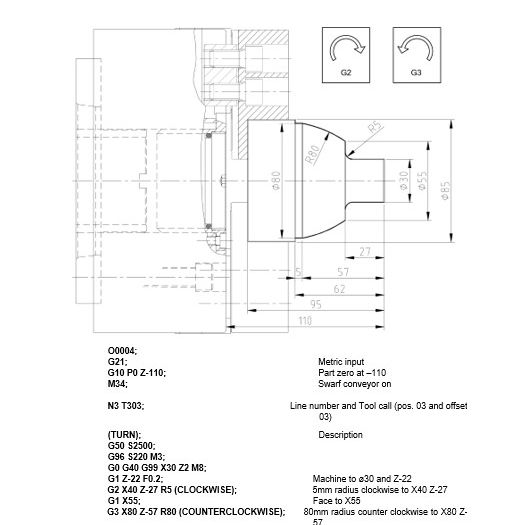

Explanation of G code groups, modal, non-modal and active at start

G Codes –

Group 7 – Tool nose compensation (G40, G41, G42)

M functions for the spindles (Group 1)

M functions for turret (Group 2)

M functions for clamping (Group 3)

M functions for the coolant valves (Group 4)

M functions for the axes (Group 11) (mirror image etc)

M functions for the handling system

Explanation of Siemens cycles: Cycle82 – Drilling, Cycle84 – Rigid tapping, Cycle93 –

Grooving, Cycle94 – Undercut, Cycle95 – Roughing, Cycle96 – Thread undercut, Cycle97 – Thread cutting

Explanation and use of Wait marks

Drilling and Milling

Positioning of the spindles (SPOS, SPOSA etc),Machining planes (G17, G18, G19)

G19 Ð C used as a circular axis

G17 Ð Axial machining as a linear axis (Transmit, with and without Y axis)

G18 Ð Radial machining (with Y axis)

Write Example program

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.